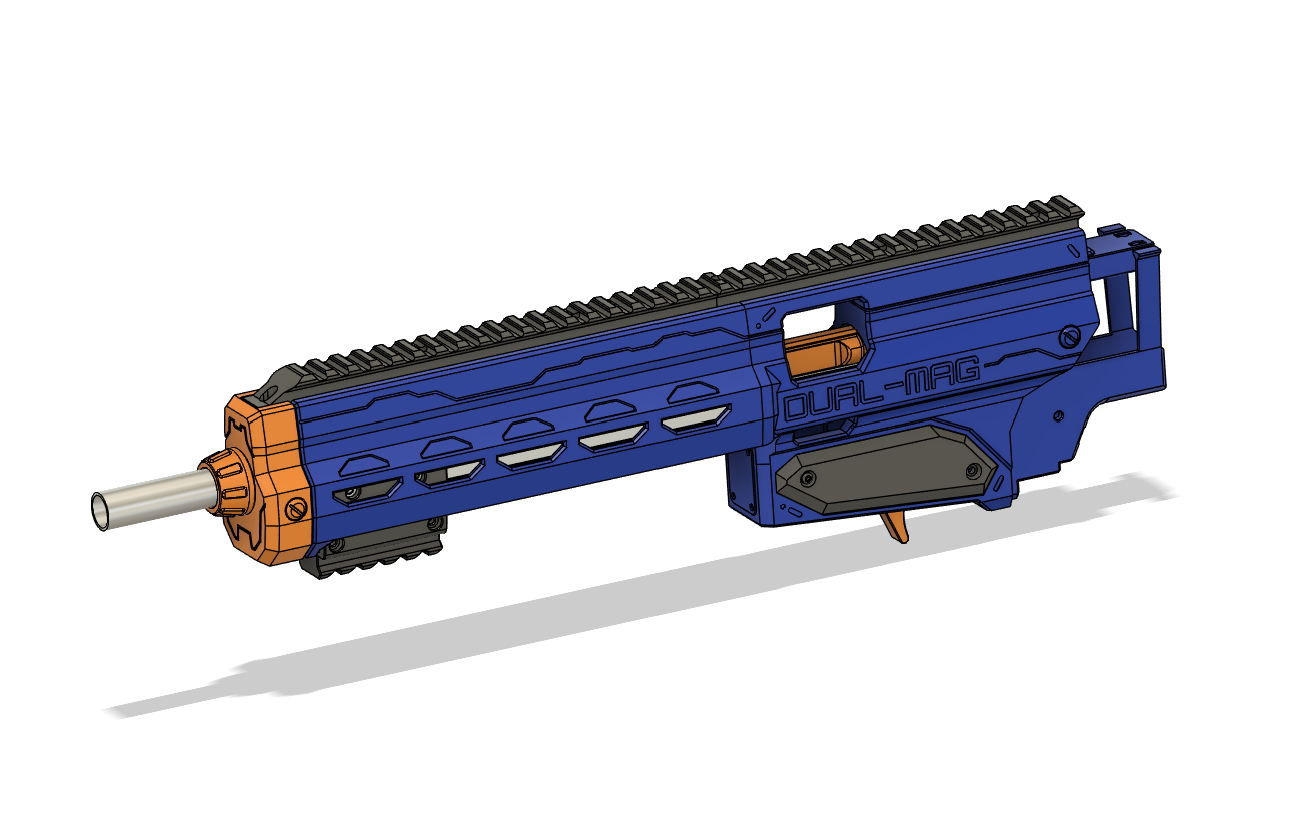

This is the Dual-Mag, a feature-rich blaster built from a mostly forgotten gem; the Nerf Dualstrike. Back in the day these pistols could be modified to hit over 300fps, so I thought “what if it could be magazine fed”. Years of planning later and almost a year of design work and testing it’s finished. And yes it can still hit over 300fps.

Features and specifications:

- Access to the internals with 4 thumbscrews -> 30 second spring swaps

- Capable of under 100fps up to over 300fps -> use one blaster for any fps cap

- One of the smoothest primes on any blaster without needing a linear rail

- 84CCs of plunger tube volume, which can be reduced down to 27CCs with different prime length plunger rods

- Upwards offset pusher makes the blaster more compact and allows easier aiming

- Built to last -> tested for months on end without part breakages

- Can use skinny springs such as K25 as well as larger diameter Lynx springs

- 3 different stock options -> proprietary printed stock, N-Strike stock mount, or picatinny stock mount

- Hardware-less barrel collet that actually holds onto your barrels

- Aluminium and brass barrel support without being locked into one ecosystem

- Option of using the stock plunger tube or a replacement one for higher fps and better shot consistency

- Very accessible hardware -> bearings and aluminium bars can be left out for a low budget build

- Gravity drop magwell and skinny pusher combo for lightning fast reloads

- Absolutely no print rubbing noises when priming the blaster

- Hidden storage on the blaster for 2 spare pusher o-rings

- 4 styles of trigger for additional customisation

- Blaster can be easily split up for transport within minutes

- Printed thumbscrews that can be used for other blasters

- Two very robust sling points you can rely on for holding the blaster

- Extremely in-depth instructions including a part picking guide and a colour guide

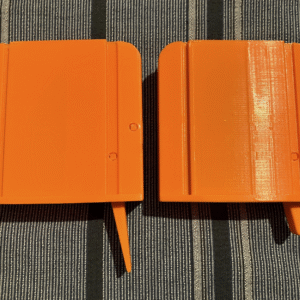

- All parts are pre-oriented for printing and use little support material

Includes 83 different STL files for ultimate customisation. That’s setups for the stock Dualstrike plunger tube or a replacement one, cutting guides for the aluminium bars and plunger tube, 3 different stock options, 7 different plunger rod options, 4 different trigger options, and support for both aluminium and brass barrels. There’s nearly limitless ways you can set up your Dual-Mag.

Build instructions: https://docs.google.com/document/d/1FwFYfcba1A_85FVeNrz2GNO8iTmwqg6iVIfeh7LKA30/edit

View other people’s Dual-Mag setups and add your own here: https://docs.google.com/spreadsheets/d/1VMRCH-oRMstqYYbp3dcvYBsHjTY0-2jcuyJyqVIzaUs/edit

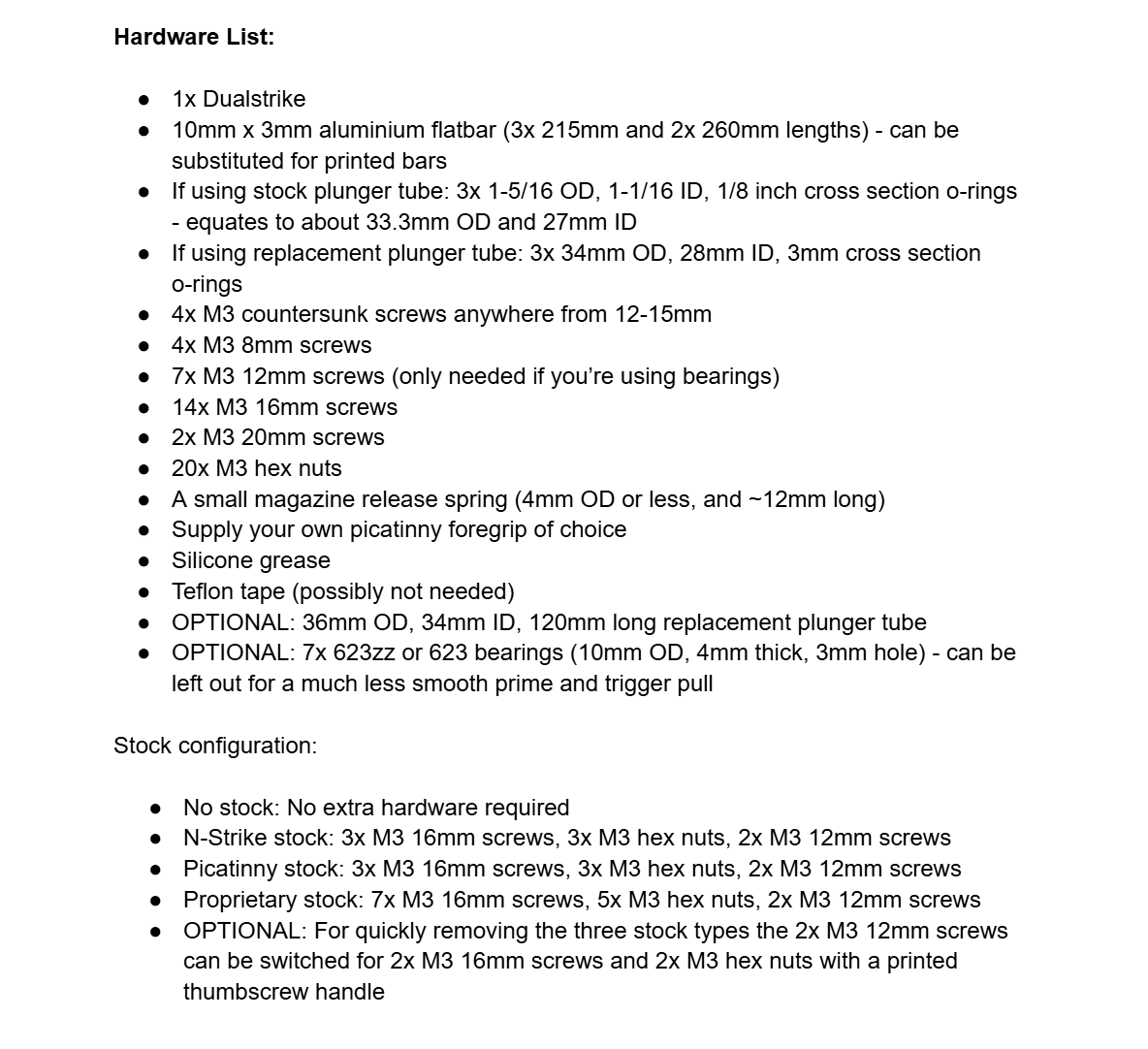

Hardware list:

- 1x Dualstrike

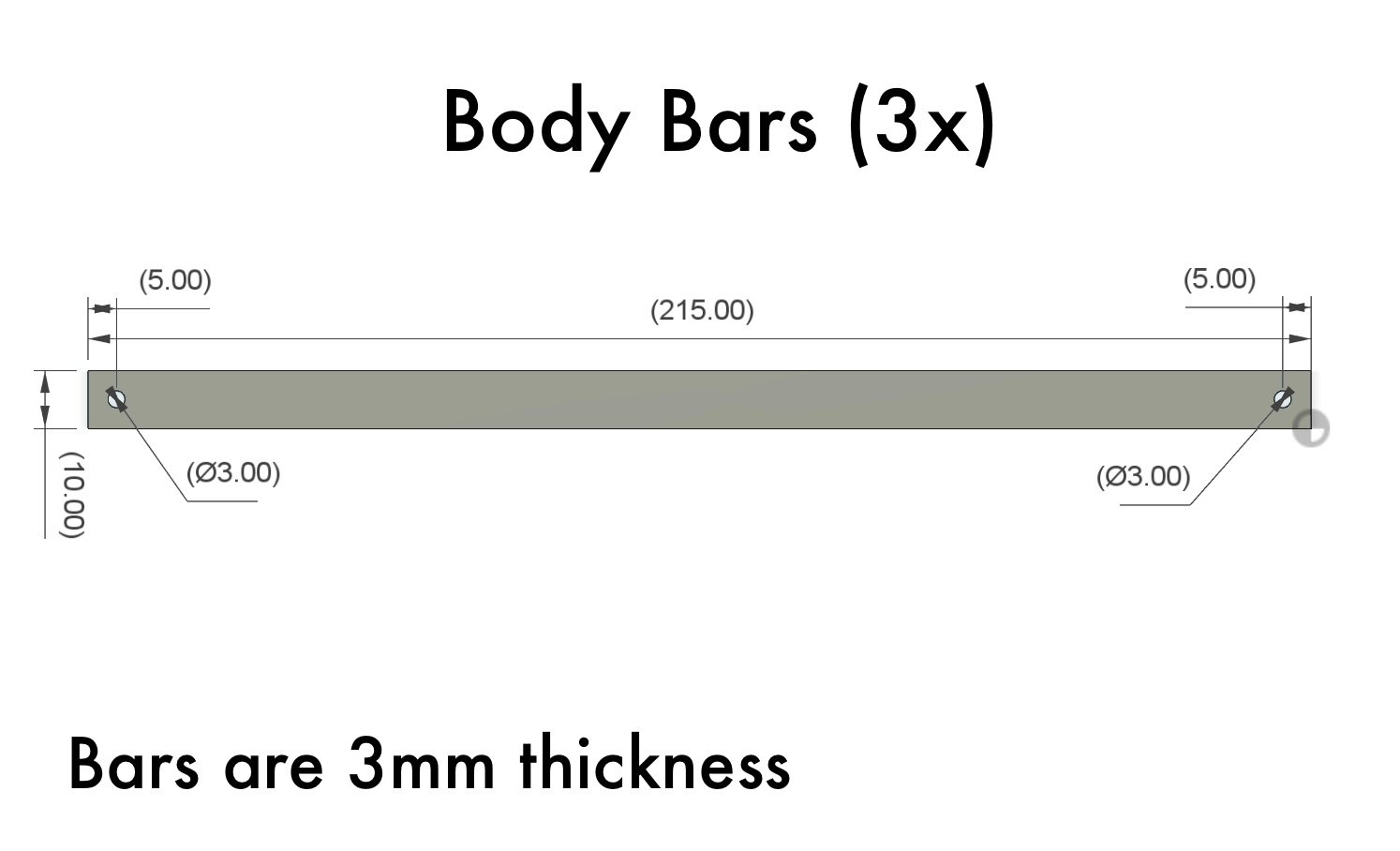

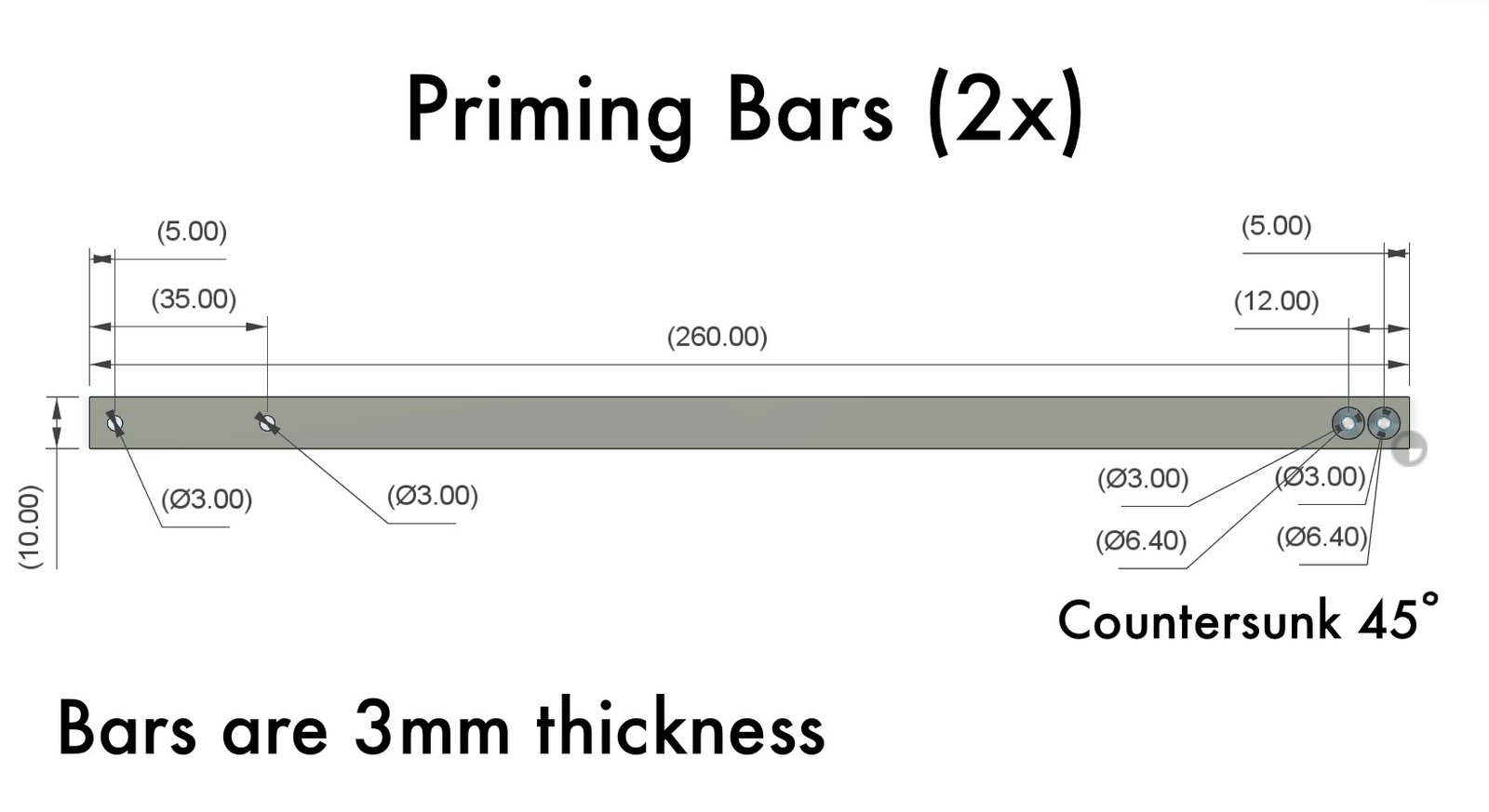

- 10mm x 3mm aluminium flatbar (3x 215mm and 2x 260mm lengths) – can be substituted for printed bars

- If using stock plunger tube: 3x 1-5/16 OD, 1-1/16 ID, 1/8 inch cross section o-rings – equates to about 33.3mm OD and 27mm ID

- If using replacement plunger tube: 3x 34mm OD, 28mm ID, 3mm cross section o-rings

- 4x M3 countersunk screws anywhere from 12-15mm

- 4x M3 8mm screws

- 7x M3 12mm screws (only needed if you’re using bearings)

- 14x M3 16mm screws

- 2x M3 20mm screws

- 20x M3 hex nuts

- A small magazine release spring (4mm OD or less, and ~12mm long)

- Supply your own picatinny foregrip of choice

- Silicone grease

- Teflon tape (possibly not needed)

- OPTIONAL: 36mm OD, 34mm ID, 120mm long replacement plunger tube

- OPTIONAL: 7x 623zz or 623 bearings (10mm OD, 4mm thick, 3mm hole) – can be left out for a much less smooth prime and trigger pull

Stock configuration:

- No stock: No extra hardware required

- N-Strike stock: 3x M3 16mm screws, 3x M3 hex nuts, 2x M3 12mm screws

- Picatinny stock: 3x M3 16mm screws, 3x M3 hex nuts, 2x M3 12mm screws

- Proprietary stock: 7x M3 16mm screws, 5x M3 hex nuts, 2x M3 12mm screws

- OPTIONAL: For quickly removing the three stock types the 2x M3 12mm screws can be switched for 2x M3 16mm screws and 2x M3 hex nuts with a printed thumbscrew handle

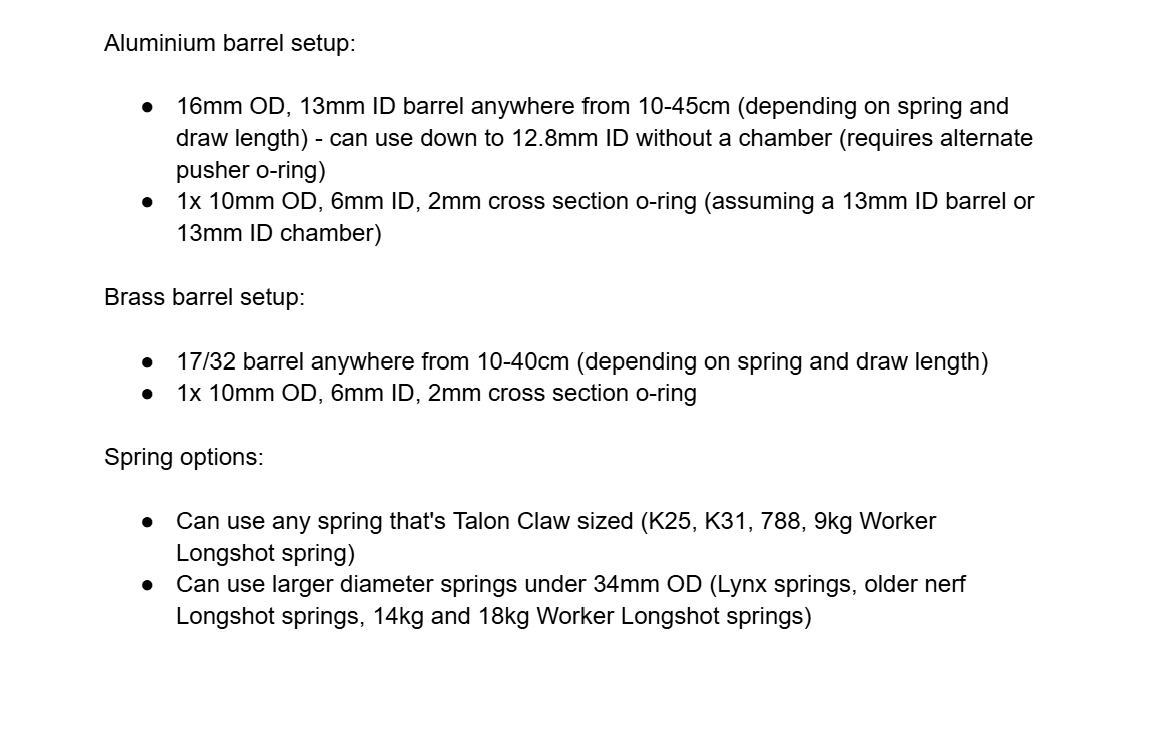

Aluminium barrel setup:

- 16mm OD, 13mm ID barrel anywhere from 10-45cm (depending on spring and draw length) – can use down to 12.8mm ID without a chamber (requires alternate pusher o-ring)

- 1x 10mm OD, 6mm ID, 2mm cross section o-ring (assuming a 13mm ID barrel or 13mm ID chamber)

Brass barrel setup:

- 17/32 barrel anywhere from 10-40cm (depending on spring and draw length)

- 1x 10mm OD, 6mm ID, 2mm cross section o-ring

Spring options:

- Can use any spring that’s Talon Claw sized (K25, K31, 788, 9kg Worker Longshot spring)

- Can use larger diameter springs under 34mm OD (Lynx springs, older nerf Longshot springs, 14kg and 18kg Worker Longshot springs)

Angel (verified owner) –

Increíble, de un lanzador olvidado se puede crear este monstruo, felicitaciones al diseñador, voy a construir dos.