Only logged in customers who have purchased this product may leave a review.

Designer: Detroit Dartworks

Accessories/ModsCheetah 2 One Pull Kit (v5.1) + Zoomie Stock + C2OP Accu-Nub .STL files – Toy Foam Dart Blaster Accessory

€8.50

These are digital .stl files to print a bolt on kit for the Worker Cheetah 2 foam dart blaster that allows the user to close the barrel to chamber a round and prime the blaster simultaneously, reducing the number of steps in the firing sequence and also relocating those steps to the rear of the blaster; this means less reaching and faster pewpewing.

This kit consists of 5 printed pieces which assemble together to clamp onto the barrel of the blaster and provide a pull handle inline with the rear priming handle. This allows the user to simultaneously chamber a round and prime the blaster, speeding up the firing process. The kit also acts as a picatinny rail riser over the existing picatinny rail on the top of the blaster. There are 3 additional optional files: a Collet Wrench to help you tighten the collet to the barrel, an elongated Front piece for use with shorter 250mm threaded rods, and a slightly tighter collet nut if the standard one is not able to grip the barrel tightly enough.

You can see a brief demonstration video here (this is a v1 kit, so it may look a bit different) (apologies for the poor audio quality): https://youtu.be/7gMJtqXz7Yw

Assembly/Installation guide here: https://youtu.be/BZrNj0p9mj4

Materials required: (Note: Comparable hardware of the m5 or #10-24 types should be compatible but have not been tested)

-a Worker Cheetah 2 blaster

-2 12 inch #10-32 threaded rods (optional file is included to accommodate the old version shorter rods of ~250mm)

-1 1¼ inch #10-32 screw

-7 #10-32 hex nuts

-2 #10-32 cap or lock nuts

-a 3d printer with build area of at least 170mm in X, Y, and Z axii to print parts

Materials recommended:

-rod covers/sleeve material: I recommend 5/16OD 3/16ID polyethylene tubing

-3/8 sized wrench and/or socket

Instructions are included in the fileset.

v5.1 Update

1. Tweaked the nut recesses on the “Front” & “Front Long” to be a little deeper to account for printer tolerances.

2. Updated the “Front Short Rods” optional file and changed name to “Front Long”. Added lower nut recesses for easier use with 12″ rods and updated the style of the underside of the piece to completely match the styling update on the v5 “Front”.

3. Added a new optional file “Collet Looser” to account for printer tolerances. Use this if you find your Collets are too wide for the Front threads or too tight for the barrel to fit through.

v5 Update

1. Redesigned the collet system. New collet is an OldFusionDesigns style one utilizing a printed collet nut. The “Collet” & “Front” have changed, and a new part, the “Collet Nut” has been added. v5 Collets and Fronts are only compatible with each other NOT earlier versions, however, they are compatible with the v4 Rail & Pull and the Collet Wrench (those parts have not changed in the v5 update).

v4 Update

1. Switched from metric (m5) to imperial (#10-32) hardware (see Hardware requirements above) & most notably increased the length of the threaded rods to 12 inches.

2. Minimized Front to reduce weight

3. Tweaked Front, Rail, & Pull designs to accommodate new hardware standards. Due to this, those three v4 parts are NOT cross-compatible with earlier versions.

4. Pull design changed to eliminate supports for printing

NOTE: m5 & #10-24 hardware should be compatible, but have not been tested. The screws and rods will fit in the holes, but the nuts may be extra loose in their recesses. The threaded rods will need to be ~12 inches long to work with the standard v4 Front. An optional “Front ShortRods” file is included to work with the old ~250mm rod lengths.

v3.2 Update

1. New redesigned, single print “Rail” replacing “Rail1” and “Rail2”

2. One fewer m5x30mm & m5 hex nut required for hardware

3. Remixed the “Collet Wrench” to only include the required wrench size

v3.1 Update

1. Reinforced the “Pull” to help prevent breaking with more brittle filaments like Silk PLA

v3 Update

1. “Front”, “Front Long”, “Rail1”, “Rail2”, and “Pull” were all widened by 3mm and had the channels for the threaded rods shifted 1.5mm towards the outer edges to accommodate m5 screws with extra tall heads for holding the Rail1 & Rail2 pieces to the picatinny rail of the blaster. Any “v3” piece is NOT compatible with v1 or v2 pieces.

2. Tolerances for the picatinny tightened up for “Rail1” and “Rail2”.

3. A small visual tweak to the “Pull” to fit with the added width.

v2 Update

Based on feedback, requests, and late night design ideas, the One Pull kit is being updated to version 2. Here are the changes and additions to the fileset:

1. “Front” & “Front Long Rods” – The biggest change is here. No more m3 screws! Barrel is now held by a fully 3d printed collet. (Original design courtesy of Captain Slug and included with their permission)

2. “Clamp” & “Clamp Squared” – Removed

3. “Collet Wrench” – Added to assist with tightening the barrel collet. (Designed by Vikinger/IvaldiIndustries and included with their permission)

4. “Pull” – Removed hex nut recesses to allow tightening of threaded rods via the cap/lock nuts

5. “Rail1” & “Rail2” – Widened channels for threaded rods to 9mm diameter in order to accommodate 5/16ths inch tubing/sleeving for use as threaded rod covers.

Earlier version files are still included with the fileset for anyone who wants them or prefers them, along with their respective instructions pdfs.

Each purchase allows for the production of as many OP kits for personal use as you like OR 1 sold kit. For additional sales, purchasing another license is required.

If you are interested in producing these commercially please contact me to discuss licensing.

ZOOMIE STOCK

These are the digital .STL files to 3d print a brace / stock for the Worker Cheetah 2.0 Blaster.

The fileset contains 3 pieces which print without supports and when assembled attach to the bottom of the grip on the Cheetah 2.0. The stock can be shouldered or used as a pseudo pistol-brace. Assembly instructions are included in the fileset.

REQUIRED TOOLS & HARDWARE:

Screwdriver or Allen Key

4 1 inch #10-32 screws

4 #10-32 hex nuts

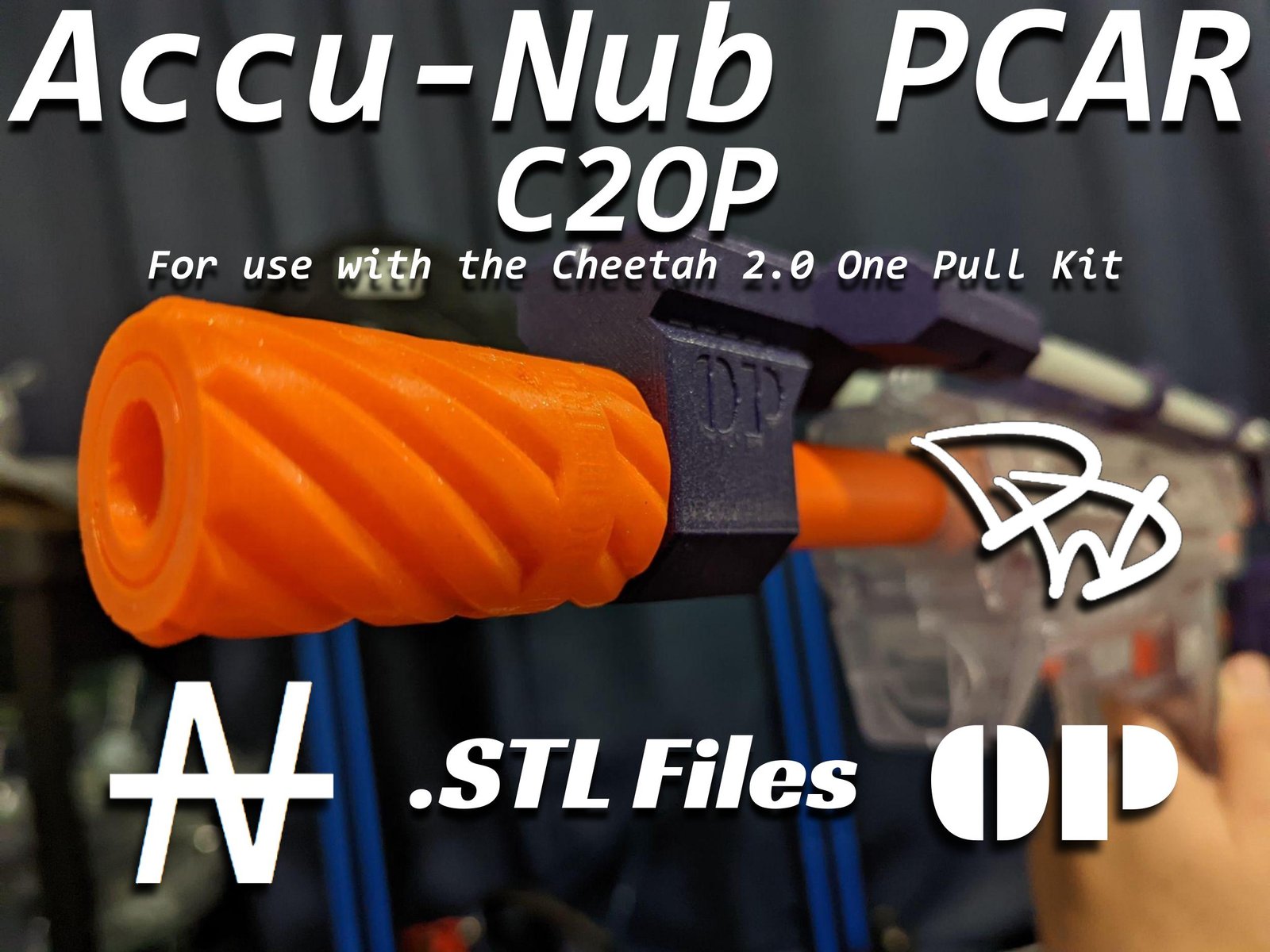

ACCU-NUB PCAR

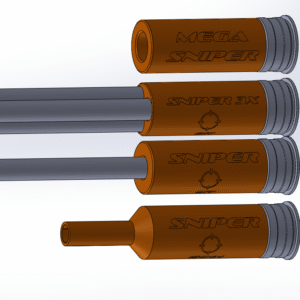

The Accu-Nub PCAR is a fully 3D printed rifled muzzle for foam dart blasters. The “Tetra-Twist” rifling combines 4 constant points of contact to center darts and apply spin to them as they leave the barrel of a blaster, improving accuracy, while the shortened contact area reduces fps loss. The C2OP version of the Accu-Nub shrouds the end of the barrel and threads into the Front of the One Pull kit using the same collet insert as the One Pull kit. This has the added benefit of simplifying installation of the One Pull kit by giving it a fixed front point.

EASY INSTALLATION:

1. Make sure the Front of the One Pull kit is in place over the barrel of the Cheetah 2.0.

2. Slide the collet insert from your Cheetah 2.0 One Pull kit onto the barrel.

3. Place the Accu-Nub over the barrel of the Cheetah 2.0 and slide it down until the barrel seats in place.

4. Screw the Accu-Nub down into the Front of the Cheetah One Pull Kit. This should draw the Front of the One Pull kit towards the end of the barrel.

5. Once tightened, proceed with installation of the One Pull kit.

Reviews

There are no reviews yet.